Intel Corporation was founded in 1968 and has grown into the world’s largest semiconductor chipmaker. The company pioneered the x86 architecture for microprocessors that became the dominant computing platform for personal computers and servers. By the 2000s, Intel controlled over 80% of the global PC and server CPU market, enjoying healthy profit margins.

However, the computing industry was shifting towards smaller, more power-efficient chips for emerging segments like netbooks, tablets, and smartphones. Intel’s main competitors like AMD and VIA Technologies moved quickly to offer low-cost processors for these mobile devices. Intel struggled to compete, as its complex, power-hungry chips carried higher costs.

To stay relevant, Intel needed to develop energy-efficient processors at price points attractive to mobile device manufacturers. In 2008, the company launched its Atom processor, designed specifically for netbooks and priced around $20.

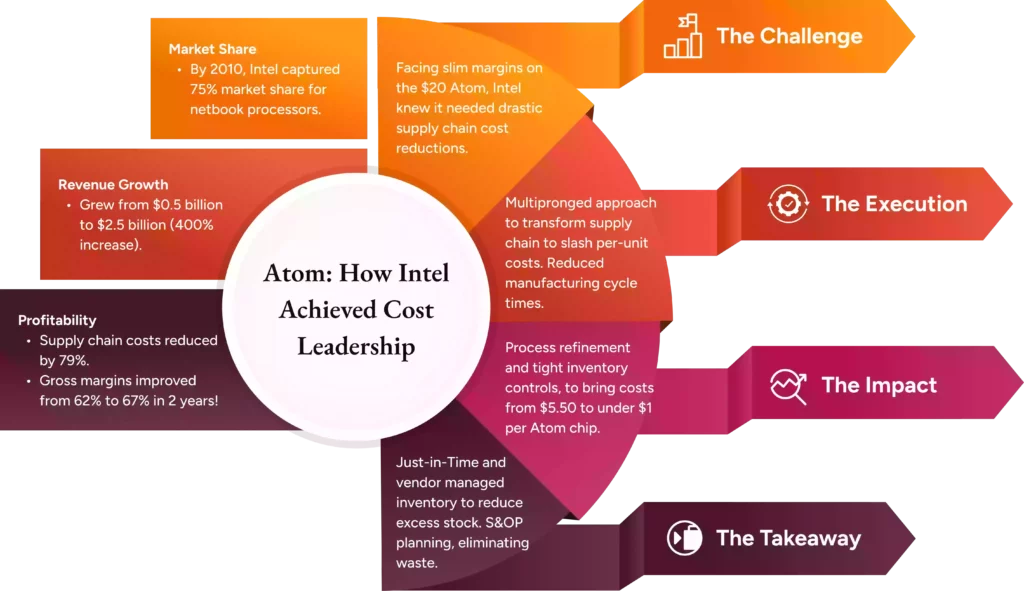

The challenge was that with a full supply chain cost of $5.50 per chip, Intel would see extremely thin profit margins on the Atom. To make the product viable and avoid losing market share in the crucial entry-level computing market, Intel needed to significantly reduce the Atom’s operational costs.

Implementation

To implement its cost leadership approach, Intel made systemic changes across manufacturing, supply chain, and marketing. In manufacturing, Intel optimized its high-volume facilities in Malaysia with automated equipment to improve productivity.

The company also overhauled testing protocols, slashing validation time from 5 days to 2 days. Lean principles were deeply ingrained, eliminating any waste on the production line.

To reduce inventory costs, Intel transitioned suppliers to a vendor managed model for just-in-time delivery while leveraging economies of scale in procurement. Distribution was streamlined by cutting unnecessary handling and air freight expenses.

On the marketing side, Intel focused spend on low-cost digital channels, economical packaging, and online brand promotion. By addressing cost drivers across the entire value chain, Intel took an integrated approach to ingraining a culture of efficiency surrounding the Atom.

This multifaceted execution strategy enabled dramatic bottom-line reductions, propelling Intel and Atom to monumental heights!

Impact

By aggressively slashing supply chain costs, Intel was able to undercut competitor pricing for low-cost mobile processors. Despite initial costs of $5.50 per chip, Intel was able to reduce expenses by over 80% to under $1 per Atom.

This enabled Intel to offer the Atom at ~ $20 and still maintain profitability. Intel’s rivals were unable to match this low price point, as their processes lacked Intel’s economies of scale and lean efficiency.

The attractively priced Atom quickly surpassed competing chips from AMD and VIA Technologies after its launch. Intel rapidly captured a dominant 75% unit share in the netbook processor market in just two years thanks to the Atom’s unmatched affordability.

The company could profitably undercut rivals and attract high-volume business at price points competitors could not viably match. Thus, establishing Intel as the leader in manufacturing of low-cost microprocessors.

Key metrics

Market Share

- Pre-Atom, Intel had 0% market share in low-cost mobile processors.

- By 2010, Intel captured 75% market share for netbook processors with the Atom.

Revenue Growth

- From 2009-2010, Intel’s revenue from Atom chips grew from $0.5 billion to $2.5 billion (400% increase).

Profitability

- With supply chain costs reduced by 79%, Intel achieved healthy profit margins on the $20 Atom.

- Atom gross margins improved from 62% in 2009 to 67% by 2011.

Intel Supply Chain – A New Frontier

- Facing slim margins on the $20 Atom, Intel knew it needed drastic supply chain cost reductions.

- The company employed a multipronged approach to transform its supply chain and slash per-unit costs. Intel reduced manufacturing cycle times.

- Moving to just-in-time components and vendor managed inventory helped to minimized excess stock. Further savings came from formalized S&OP planning, eliminating waste.

Through process refinement and tight inventory controls, Intel supply chain costs were ultimately slashed from $5.50 to under $1 per Atom chip. The company’s relentless focus on maximizing efficiency and eliminating waste at every step enabled Intel to achieve the cost reductions vital to the Atom’s success!

Key Take Away(s) of Intel Supply Chain

By tenaciously fine-tuning processes across the value chain, Intel was able to transform manufacturing agility and profitably achieve disruptive low pricing.

The company learned that cost competitiveness opens new strategic opportunities. Critically, Intel proved cost leadership and differentiation can complement each other – Atom’s affordability expanded market reach without compromising Intel’s quality reputation!

If you’d like to read more about how companies, organizations, and brands are reinventing success with out-of-the-box approaches and innovation, stay tuned, and subscribe to our newsletter, to receive interesting content and more, straight to your inbox!